IAPQR Transactions - A UGC-CARE Listed Journal

Published in Association with Indian Association for Productivity, Quality and Reliability

Current Volume: 49 (2024-2025 )

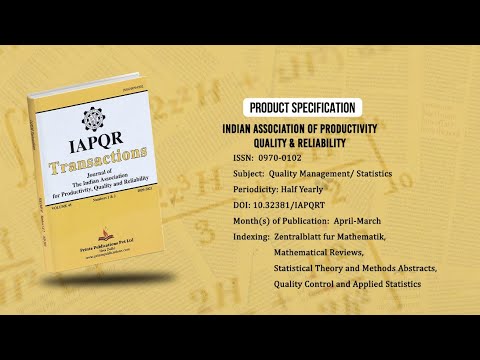

ISSN: 0970-0102

Periodicity: Half-Yearly

Month(s) of Publication: September & March

Subject: Quality Management/Statistics

DOI: 10.32381/IAPQRT

Modified Control Charts with Warning Limits to Detect Shifts in the Process Mean and for Increase in Fraction Nonconforming

By : R. N. Rattihalli, M. P. Gadre, R. A. Patel

Page No: 53-74

Abstract:

In this article, for univariate processes, we propose improved control charts useful to detect shift in the process mean and to identify increases in the fraction nonconforming. These modified control charts are intended to reduce the out-of-control ‘Average Time to Signal’ (ATS). When the charting statistic is inside the control limits, but close to control limits (between the warning and the control limits), the process may not be operating properly. In such situations, to have substantial/additional information about quality of the process, in this article, we propose ‘Modified Control Chart with Warning Limits’ (MCCWL) to detect shifts in the process mean, increases in fraction nonconforming and to monitor shifts in the mean vector. It is modified in the sense that a rule is defined to stop the sampling and to declare the process as out of control. The corresponding expression for Average Run Length (ARL) is obtained. The design parameters are obtained under ‘Average Time to Signal’ (ATS) criterion. The proposed charts namely, ????? ? ??, ????? ? ??,????? ? ??? are shown to perform better than their competitors considered. Abstract: In this article, for univariate processes, we propose improved control charts useful to detect shift in the process mean and to identify increases in the fraction nonconforming. These modified control charts are intended to reduce the out-of-control ‘Average Time to Signal’ (ATS). When the charting statistic is inside the control limits, but close to control limits (between the warning and the control limits), the process may not be operating properly. In such situations, to have substantial/additional information about quality of the process, in this article, we propose ‘Modified Control Chart with Warning Limits’ (MCCWL) to detect shifts in the process mean, increases in fraction nonconforming and to monitor shifts in the mean vector. It is modified in the sense that a rule is defined to stop the sampling and to declare the process as out of control. The corresponding expression for Average Run Length (ARL) is obtained. The design parameters are obtained under ‘Average Time to Signal’ (ATS) criterion. The proposed charts namely, ????? ? ??, ????? ? ??,????? ? ??? are shown to perform better than their competitors considered.

Authors :

R. N. Rattihalli

Retd. Professor, Shivaji University, Kolhapur

M. P. Gadre

Shriram Institute of Information Technology, Paniv, District Solapur

R. A. Patel

Karnatak University, Dharwad

DOI: DOI-https://doi.org/10.32381/IAPQRT.2022.46.01-02.4