IAPQR Transactions - A UGC-CARE Listed Journal

Published in Association with Indian Association for Productivity, Quality and Reliability

Current Volume: 49 (2024-2025 )

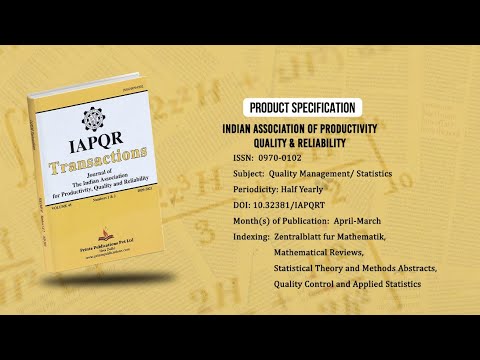

ISSN: 0970-0102

Periodicity: Half-Yearly

Month(s) of Publication: September & March

Subject: Quality Management/Statistics

DOI: 10.32381/IAPQRT

Development of a Model to Integrate Six Sigma Approaches

By : Subrata Rath, Ashis Kumar Chakraborty, Subhashis Chatterjee

Page No: 93-115

Abstract

Six Sigma was born with a disciplined problem-solving approach called D M A I C (Define, Measure, Analyse, Improve and Control) way back in 1979. The approach is data-intensive requiring statistical orientation and is used for defect reduction. Effect of such defect reduction is visible in the increased profit margin. This approach was a little silent on the waste accumulation in as-is complicated processes. Accumulated waste has direct impact on the cash flow of an organization and usually lean approach is adopted to optimise process flow to reduce, if not eliminate waste in any process. Hence, a new approach was initiated to adapt lean methodology to create better flow in the processes while continuing delivering Six Sigma results. Such approach is known as Lean Six Sigma (LSS). LSS is process flow intensive, requiring more of Industrial Engineering, Operations Research and lean orientation. Results derived from Six Sigma and Lean Six Sigma are well appreciated worldwide across the type and scale of the organizations. However, question started brewing on why the defects and waste are available in any organization in the first instance. This question designated both the Six Sigma and Lean Six Sigma approaches as reactive problem solving initiatives and gave birth of another very important initiative, named Design for Six Sigma (DFSS), to prevent defects and waste in any product and process, in its launch itself. This process is more domain discipline intensive, requiring discovery, invention and innovation. All these approaches together make more sense in business and unfortunately literature is little silent where these approaches are synchronised to leverage the business results for an organization. This paper is an attempt to create a model to integrate all these three approaches with adequate flexibility of interconnectivity within the approach elements for the overall sustainable, predictable and desirable business results. A case is also used to demonstrate the implementation of the mode.

Authors :

Subrata Pal

Shriram Institute for Industrial Research, 19, University Road, Delhi-110007, India

Ashis Kumar Chakraborty

Statistical Quality Control and Operations Research unit, Indian Statistical Institute

Subhashis Chatterjee

Department of Mathematics and Computing, IIT (ISM), Dhanbad

DOI: DOI-https://doi.org/10.32381/IAPQRT.2021.45.01-02.7