IAPQR Transactions - A UGC-CARE Listed Journal

Published in Association with Indian Association for Productivity, Quality and Reliability

Current Volume: 49 (2024-2025 )

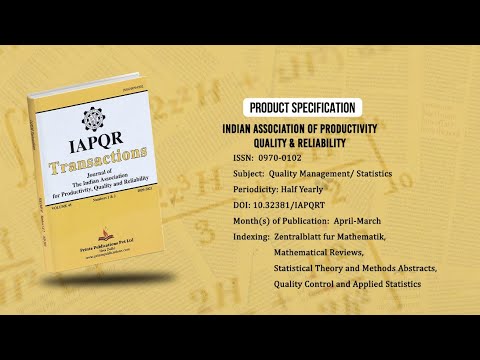

ISSN: 0970-0102

Periodicity: Half-Yearly

Month(s) of Publication: September & March

Subject: Quality Management/Statistics

DOI: 10.32381/IAPQRT

A Case Study on Implementation of Mahalanobis-Taguchi System for Multivariate Manufacturing Process Control

By : Sagar Sikder, Indrajit Mukerjee, Subhash Chandra Panja

Page No: 61-71

Abstract

In manufacturing process, quality of an end product or component is often assessed by multiple critical output characteristics (or responses). These responses are often correlated or interacting. Change in process setting condition, with an intension to improve a particular response characteristic, may adversely affect another response. In this context, researchers had proposed various parametric and nonparametric Multivariate Statistical Process Control (MSPC) charts for monitoring of correlated responses and detecting out-of-control signal. However, there is little evidence of nonparametric MSPC research to identify influential response(s) for any out-of-control situation in a manufacturing process. In this paper, Mahalanobis-Taguchi System (MTS), based on Mahalanobis Distance (MD) scale and Taguchi’s Orthogonal Array (OA) design, is explored for detecting out-ofcontrol state and identify influential response(s) for an out-of-control state. Suitability of the approach is verified using a manufacturing process case study.

Authors :

Sagar Sikder

SQC & OR Unit, Indian Statistical Institute, Mumbai, India.

Iindrajit Mukerjee

Shailesh J. Mehta School of Management, IIT Bombay, India.

Subhash Chandra Panja

Department of Mechanical Engineering, Jadavpur University, Kolkata, India.

DOI: DOI-https://doi.org/10.32381/IAPQRT.2018.43.01.4